Applications

Slab width and shape measurement

|

Overview of the Plan

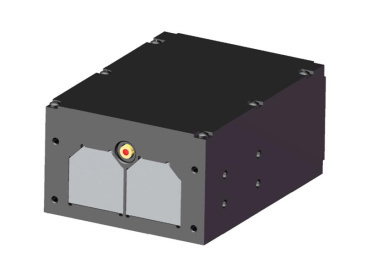

Used for real-time measurement of the width of the slab, the operator can observe the width parameters of the slab during operation through the display, and the measurement results can be transmitted to the user's computer system. The width measurement adopts the principle of laser scanning, which captures the edge information of the steel plate from two angles through two positioning scanners installed on the side of the slab. The information is sent to a dedicated high-speed digital signal processor system for analysis and processing, obtaining accurate width information of the steel plate. The equipment adopts triangulation method to avoid the influence of slab lateral movement on measurement and achieve high-precision measurement. |

|

Advantages of the plan

|

The detection distance can reach 200 meters, regardless of whether the workpiece is hot or cold

|

No reflector required | Easy to install and set up | Specially designed for harsh environments in the steel industry |

Customer Service Hotline

E-mail:swzn@surertech.cn

Official website:http://www.surertech.cn

Address: 13-14 floors, Building 1, Software Valley Headquarters Economic Park, Yuhuatai District, Nanjing City, Jiangsu Province

Sweep the two-dimensional code